Robot Teleoperation for Remote Inspection

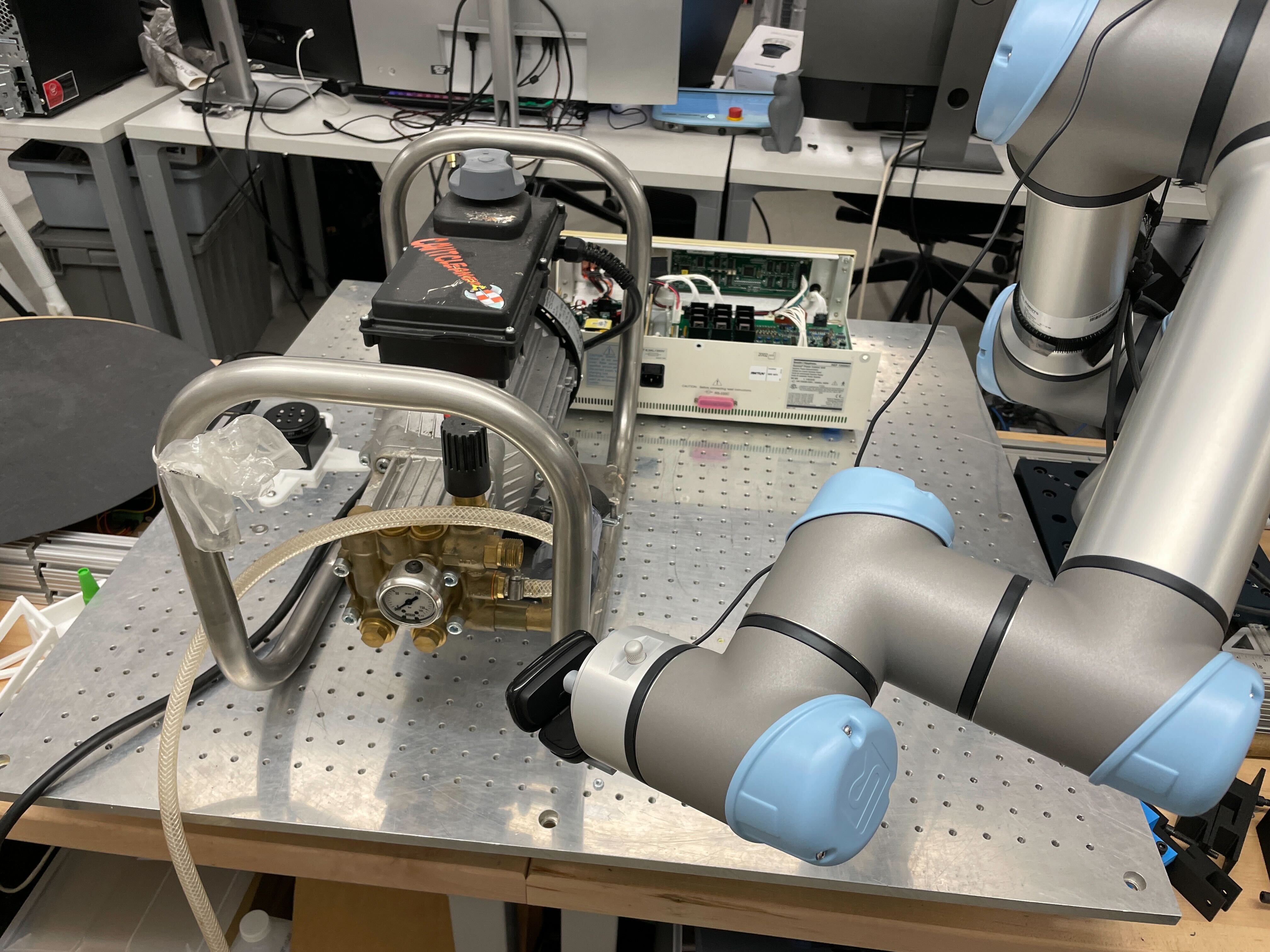

The teleoperation project was commissioned as part of an effort to develop solutions for automated factories where routine maintenance is a requirement. One half of the wheeled robot inspection system which has been planned, the manipulator teleoperation project aims to develop solutions for precise control of robot arms, controlled by an operator at a remote location. The operator may utilize a guided mode for controlling the arm, or a full manual mode to control the arm without assistance.

My teleoperation package represents a cutting-edge solution for remote robotic control, designed to provide precise, safe, and intuitive manipulation of robotic systems across various environments. By leveraging advanced communication technologies and user-centric design, the package enables operators to perform complex tasks from a safe distance.

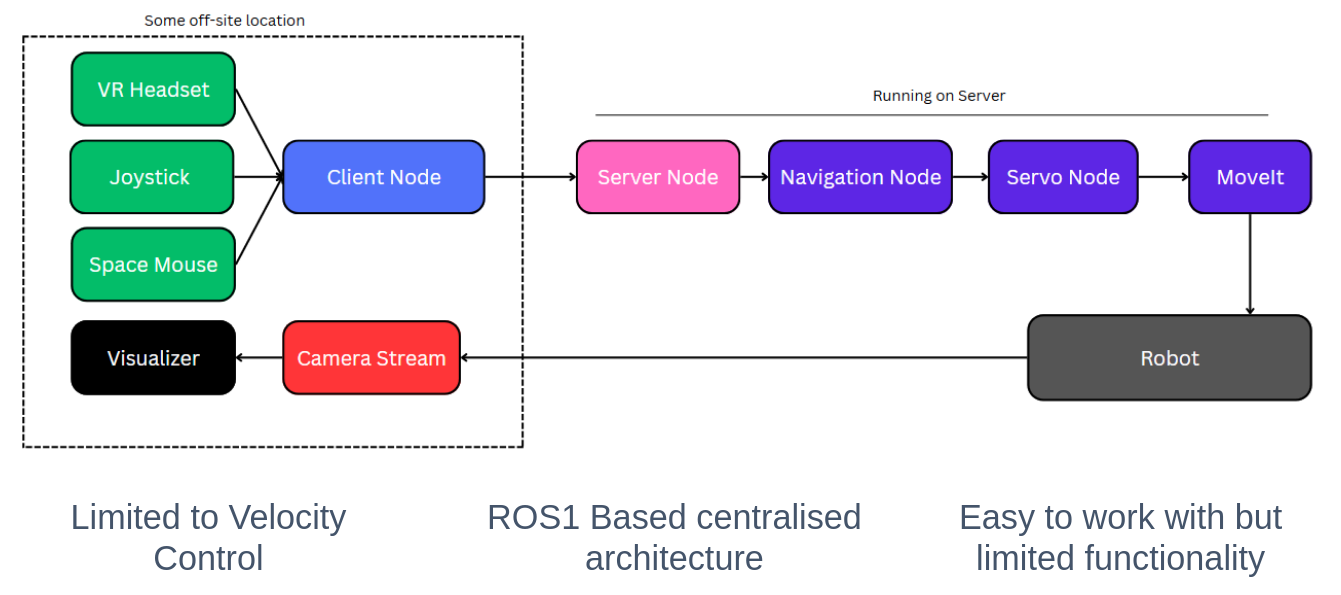

Teleoperation Architecture

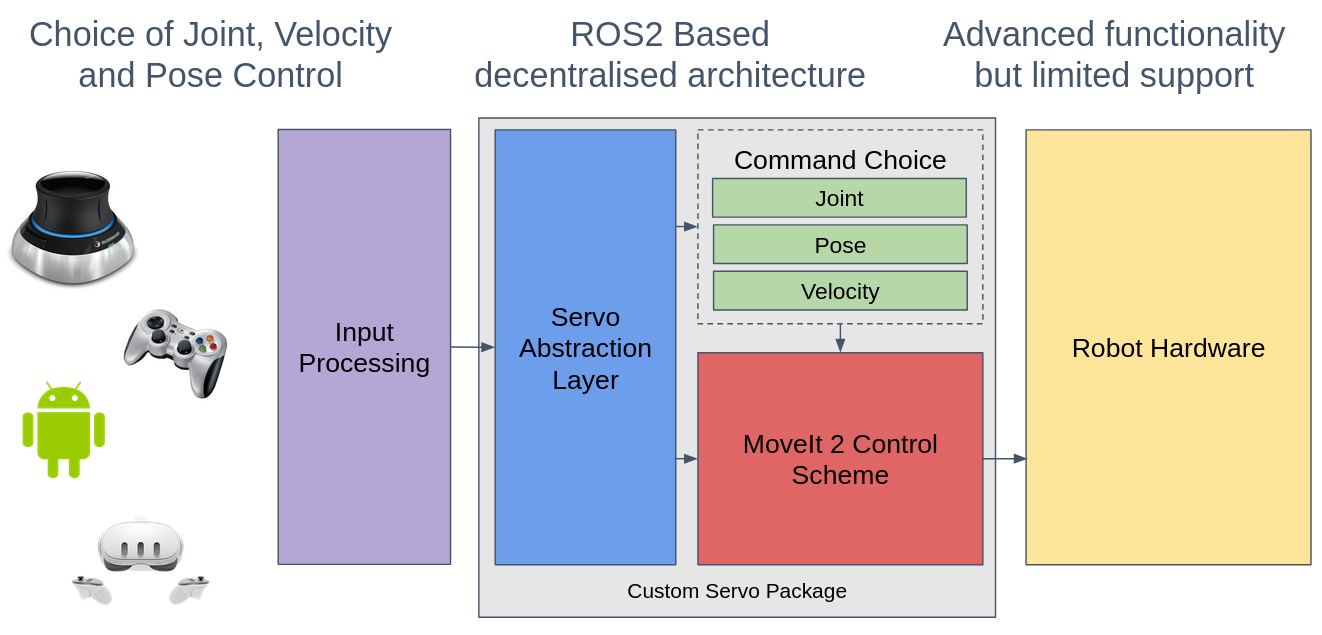

The teleoperation architecture has undergone a significant evolution, transitioning from a ROS1-based centralized system to a more sophisticated ROS2-based decentralized framework. This evolution reflects the growing demands for more flexible and robust robotic control systems.

The initial ROS1 architecture implemented a straightforward approach, channeling multiple input devices through a centralized client node. This design prioritized simplicity and ease of implementation, though it was limited to velocity-based control. The server-side components formed a linear pipeline from command processing through to robot execution, making it highly reliable but somewhat inflexible.

The transition to ROS2 brought a paradigm shift in the control architecture. The new design introduces a sophisticated servo abstraction layer that supports multiple command modalities - joint control, pose control, and velocity control. This flexibility allows operators to choose the most appropriate control scheme for their specific task. The decentralized nature of the system, combined with the custom servo package, enables more complex operations while maintaining system stability and responsiveness.

While the newer architecture demands more initial setup and offers limited support compared to its predecessor, its advanced functionality and flexible control options make it a more powerful solution for modern robotics applications. The evolution represents a shift from a "one-size-fits-all" approach to a more adaptable and capable system.

Applications

The teleoperation system has been successfully deployed across multiple industrial inspection scenarios, demonstrating its versatility and precision in quality control applications. This is done by swapping the sensor pack on the robot end-effector.

1. Structured Light Part Inspection

This application combines structured light sensing with high-precision camera systems for comprehensive part analysis. The system enables:

- 3D surface mapping for defect detection

- Real-time dimensional verification

- Non-contact measurement of complex geometries

2. PCB Inspection System

Utilizing a high-resolution camera setup, this configuration specializes in detailed PCB inspection tasks:

- Component placement verification

- Solder joint quality assessment

- Surface mount defect detection

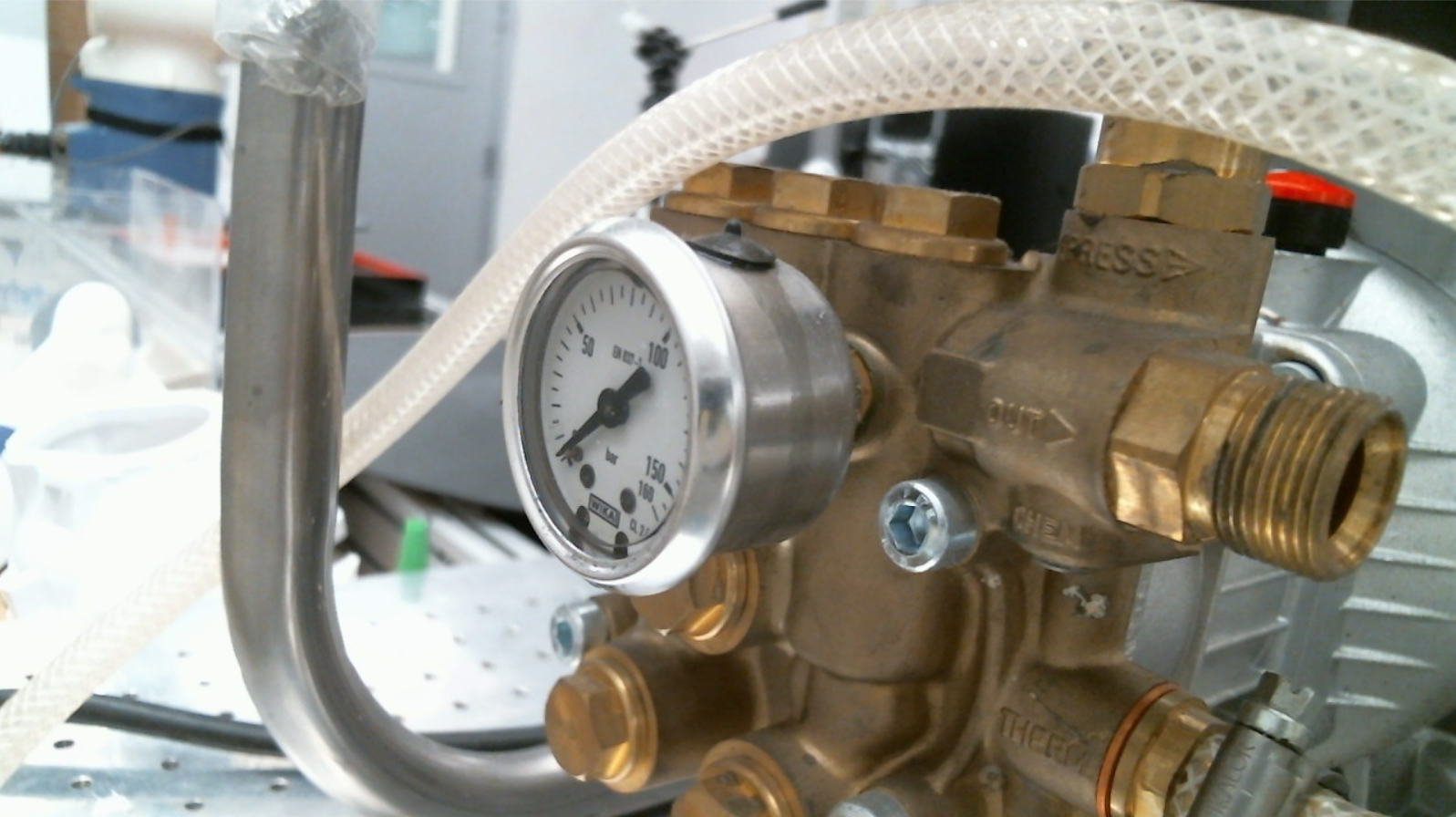

3. Mechanical System Inspection

Focused on industrial machinery inspection, this setup is optimized for:

- Precise gauge reading automation

- Pipe integrity assessment

- Sealant application verification